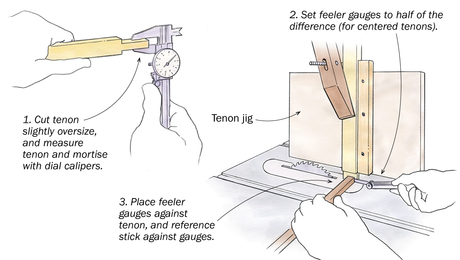

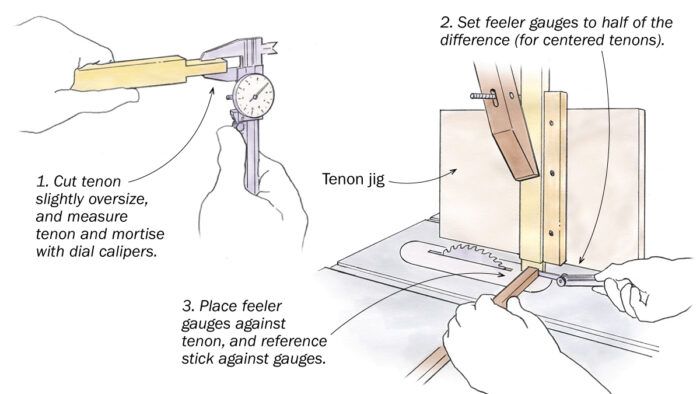

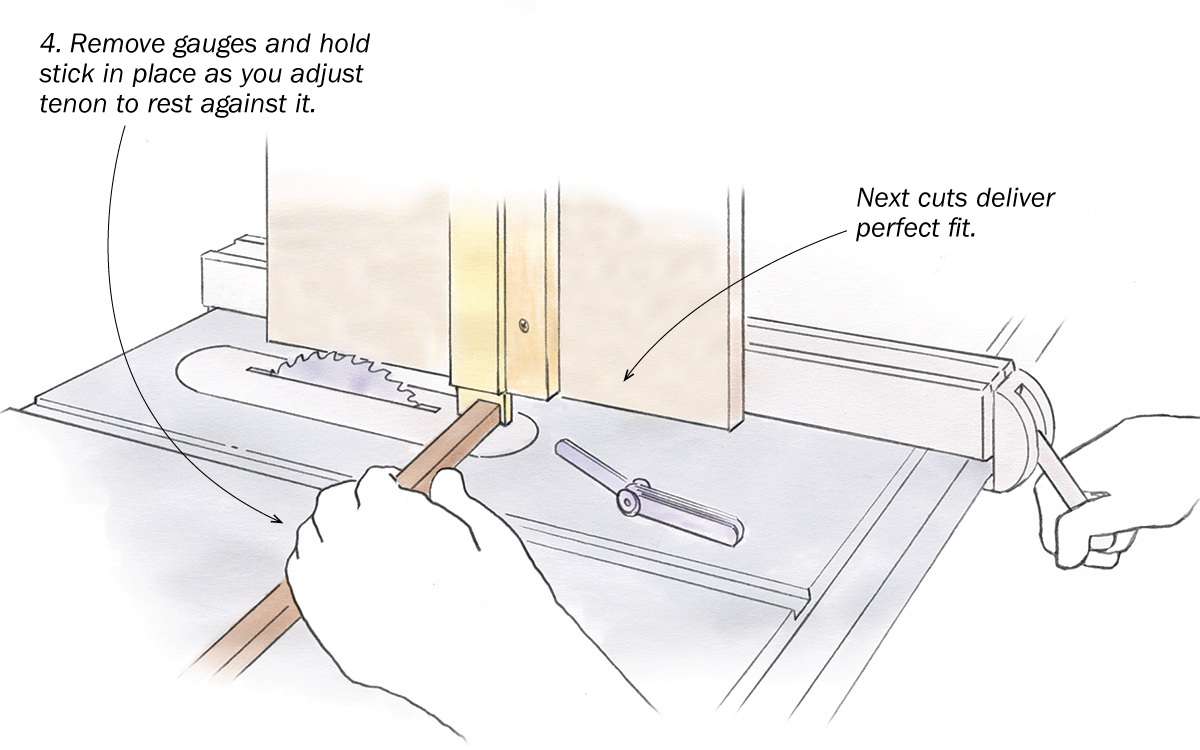

I lower tenons on the desk noticed, utilizing a jig that stands the items on finish. I’ve at all times match the tenon to the mortise by step by step adjusting the jig to sneak up on the proper tenon. It occurred to me that I might save time and enhance accuracy by teaming up my dial calipers with a set of feeler gauges.

I begin by chopping the tenon barely oversize. Then I exploit the calipers to match the tenon thickness with the mortise width. In case you are making cuts on each side of a centered tenon, you’ll must divide that distinction in half. For those who’ve acquired one cheek already lower precisely, you may take away the total distinction. Regardless of the quantity is, choose a mix of feeler gauges that matches it. With the workpiece within the jig, place the feeler gauges towards the tenon, and bump a reference piece up towards the opposite facet of the feeler gauges. Maintain the reference piece proper there, take away the feeler gauges, and regulate the jig till the tenon cheek is resting towards the reference. You’re prepared to chop the tenon to remaining dimension, and all the different tenons in your meeting as nicely, with 0.001-in. accuracy.

—BOB RIFKIN, Acton, Mass.

Illustrations by Dan Thornton

From High quality Woodworking subject #308

Make a Shopmade Desk Noticed Tenoning Jig

Workshop Tip: Outrigger steadies desk noticed tenon jig

A Slick Tenoning Jig

Join eletters in the present day and get the newest methods and how-to from High quality Woodworking, plus particular presents.