—This text is from FWW #21–Mar/April 1980.

Most areas develop no less than one timber species that’s appropriate for log work. Some typical hewing woods embrace the pines, fir, spruce, redwood, tulip poplar, and oak, however you can even hew different woods equivalent to black locust or maple. Inside a species, sure timber can be extra appropriate than others. Knots add to the work concerned, and the butt part of a tree is commonly a lot more durable than wooden a couple of ft farther up the trunk. Most tasks name for comparatively straight timber. In North America, logs are typically labored inexperienced, however most European craftsmen want to hew seasoned logs, that are much less prone to test, break up, or warp.

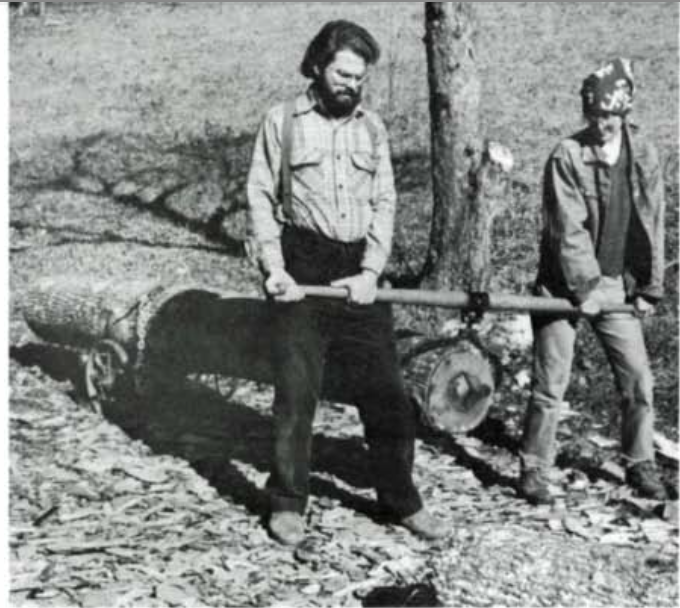

Earlier than starting, it’s essential to pay attention to the issues in coping with a cloth as heavy as logs, which when inexperienced weigh between 40 lb. and 70 lb. per cubic foot. It’s typically troublesome to get a log shifting, however when gravity takes over, the log turns into laborious to cease. At all times watch out when lifting or shifting logs. Study to make use of leg muscle tissues, which pressure much less simply than the again. Make use of levers, fulcrums, block and sort out, and rollers. Giant and small peaveys and cant hooks are nearly indispensable. I prefer to raise and haul logs with a associate on the opposite aspect of a timber provider. It consists of a pair of seize hooks that grasp from a swivel within the heart of a 4-ft. or 5-ft. pole. Every individual lifts an finish of the pole. The entrance finish of the log is within the seize hooks between them; the far finish is supported by a pair of wheels in a wood truss.

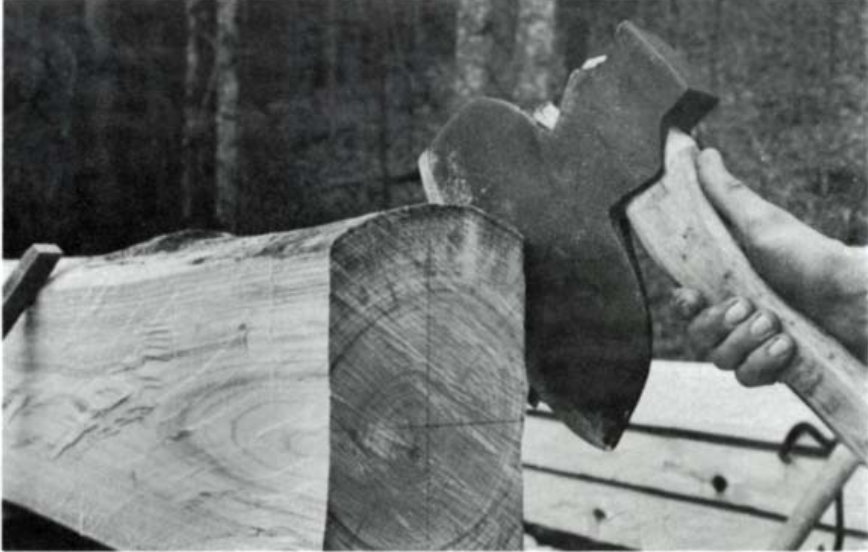

Most log hewing is completed with broad axes, however although they’re great instruments, you don’t want one to strive hewing. In truth, some rookies discover a 7-lb. to 10-lb. broad ax intimidating, awkward, and backbreaking.

The broad ax that I take advantage of has a 9-lb. head with a 13-in. leading edge. An essential characteristic of this ax, typically not understood, is that the within face of the top just isn’t flat. The aspect curves alongside a horizontal line, forming an arc about 3/16 in. deep. This causes the ax to chop with a slight scooping impact. Vertically, the inside face is completely flat from the leading edge to the ballot. Broad-ax handles differ in size from 15 in. to 30 in. For many hewing strategies, the deal with should take a radical bend instantly behind the top the place the lead hand is positioned. This offers the required clearance between the hewer’s fingers and the log.

The tactic of hewing I take advantage of was developed by Peter Gott, an completed craftsperson who has refined his hewing approach and elegance throughout 18 years of log-building. Many hew by eye, snapping one or two chalk strains down a log, after which hew. This may be tough as a result of logs taper, bend, and bulge, making it troublesome to eyeball a flat airplane. Gott’s approach, which virtually ensures good outcomes, makes use of a collection of correct pencil and chalk tips which can be all perpendicular or parallel to at least one one other, and can be utilized for hewing one, two, three, or 4 surfaces. Flat planes facilitate notch work, mortise-and-tenon joints, and different detailed refinements. You can even adapt Gott’s approach to carving and sculptural tasks.

Start hewing by barking the log. Some timber (equivalent to tulip poplar) peel in massive slabs; others require extra work. Slash a slender strip with an ax, then attempt to peel by inserting a barking spud or backyard spade on the cambium. You can even ax off bark or use an extra-large barking drawknife.

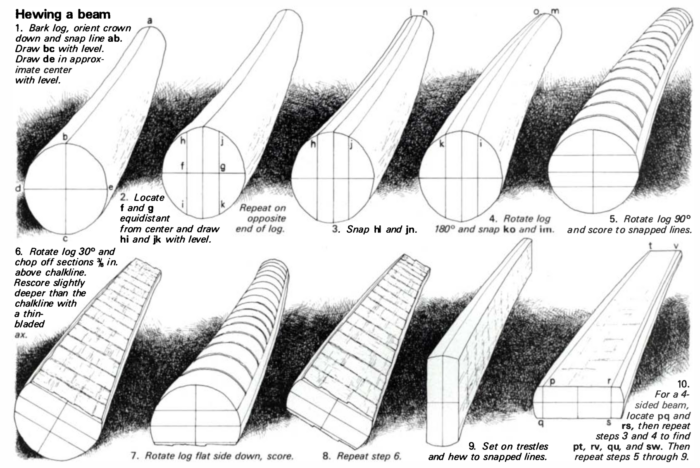

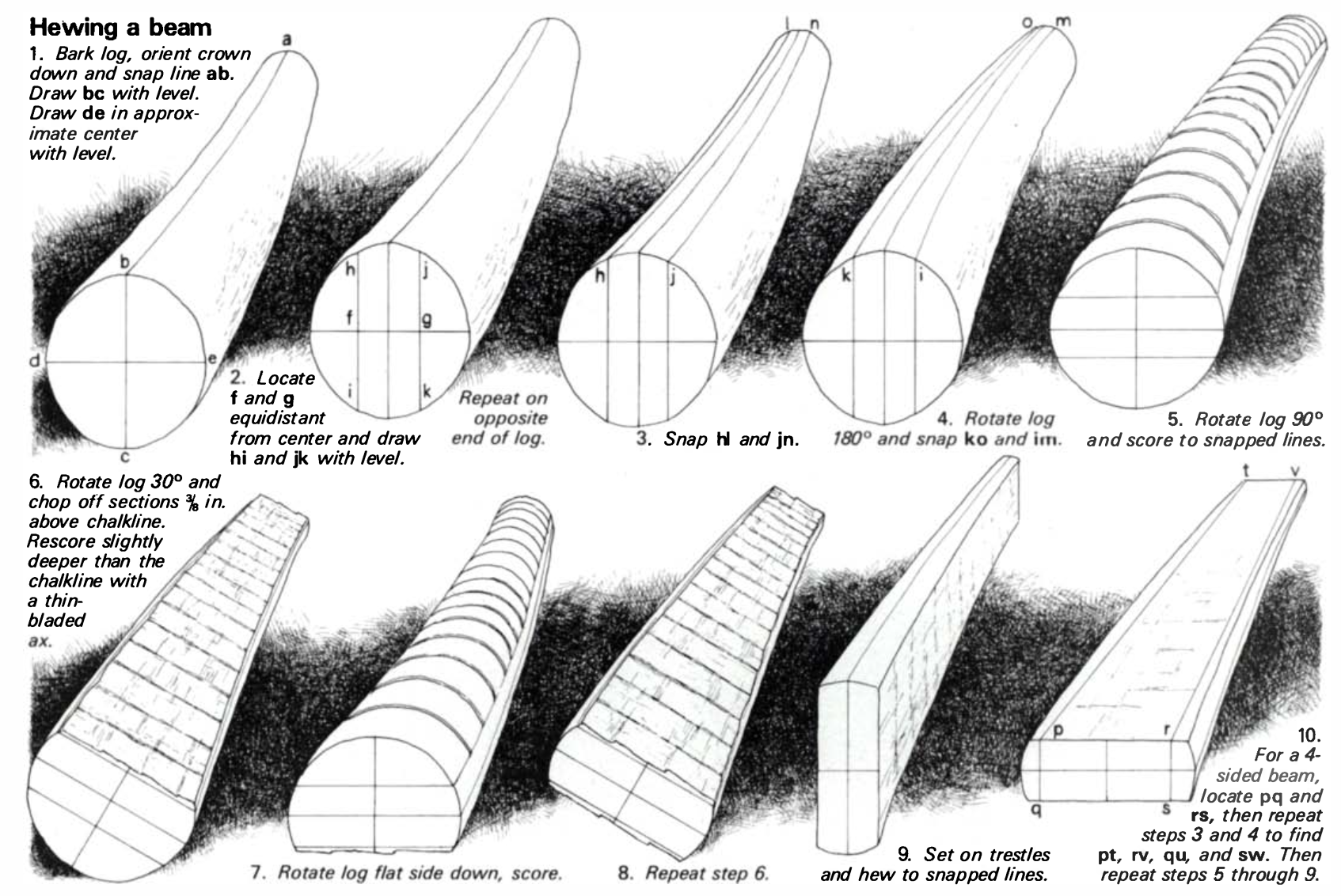

Transfer the clear log onto a pair of cribs (3-ft. to 4-ft. cross logs with heart notches to forestall rolling). Sight the log from every finish to find out dominant swag or crown, and, with a brief peavey or cant hook, rotate the log in order that it’s crown down. Put an axe by way of the loop of a chalk line and stick the purpose into the approximate heart of 1 finish of the log. Reel out the road and stick a second axe into the opposite heart, pulling the string taut. A chalk line snapped on a rounded floor can simply lead to a curve. Keep away from this by finding the angle for snapping the road with a vertically held carpenter’s stage. That is significantly essential when engaged on nonlevel floor, because it’s troublesome to evaluate plumb by eye.

Draw a vertical line down the top of the log, utilizing the extent as a straightedge. Then draw a perpendicular line someplace close to the center. Find the sting(s) to be hewn by drawing vertical strains throughout the perpendicular line. (On a log to be hewn on two sides, these strains are equidistant on both aspect from the unique vertical line.) Use your stage.

When your strains are drawn, knife a small V-notch the place they meet the aspect of the log. Repeat this process on the different finish of the log. Snap new chalk strains alongside the size of the log to find the hewing strains, utilizing the V-notches to carry the chalk line in place. Rotate the log 180° (crown up) and snap parallel hewing strains alongside the crown.

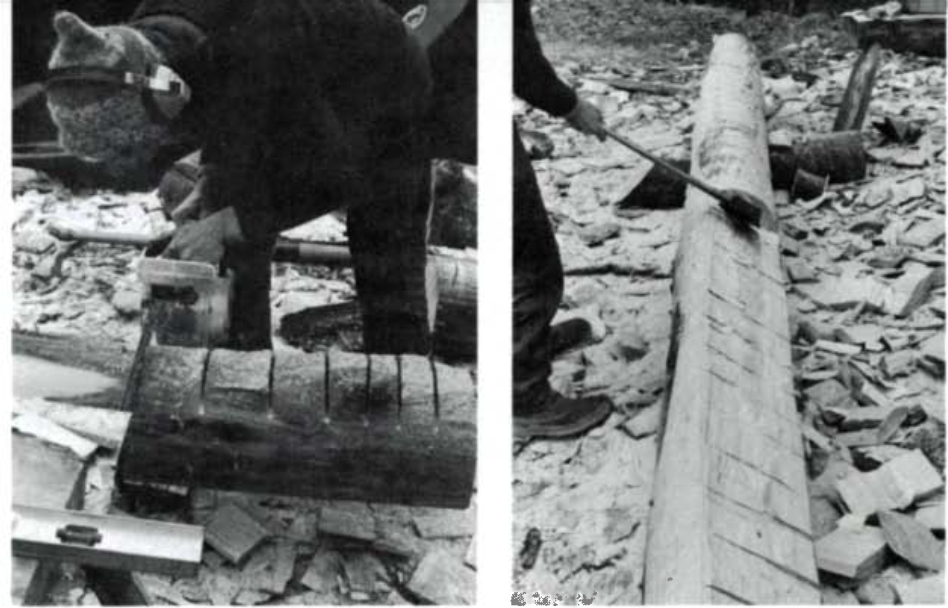

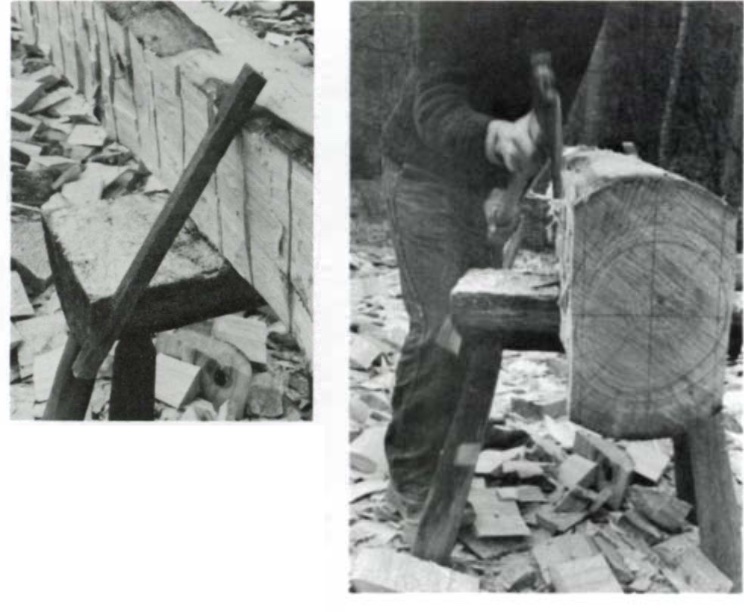

Rotate the log 90° so the aspect to be hewed faces up. Take away the majority of the waste by first scoring to the hewing line each 8 in. to 24 in. on heart, utilizing a symmetrically beveled ax, a handsaw, or a chainsaw. Then rotate the log 30° and take away the top chunk, inserting the ax edge 3/8 in. to the waste aspect of the chalk line and hanging the ballot with a mallet.

Proceed down the log, splitting wooden off and leaving the identical 3/8-in. margin above the chalk line so the broad ax, which can be used to complete the floor, can have one thing to chew into. After you’ve eliminated a lot of the waste, chop one other collection of vertical scoring marks barely deeper than the chalk hewing strains with a pointy, thin-bladed ax. These cuts ought to be about 4 in. aside; their sample will present barely after hewing is completed. Deep scoring prevents fiber from tearing inward, particularly round knots, and can also be extra enticing than tough sawkerfs. Then flip the log and repeat the whole course of on the obverse face.

Set the go browsing a pair of trestles about 30 in. excessive minus the diameter of the log (dimension of craftsperson and private choice dictate totally different trestle heights). Place the go browsing edge, and briefly maintain it regular with makeshift wedges positioned beneath. Use the extent and a vertical guideline on one finish of the log to regulate for plumb. A variance of some levels makes hewing significantly harder.

One conventional method to maintain a log regular on edge is with hewing canine—iron staples with one finish pushed into the log and the opposite into the trestle or crib log. Some massive logs could be wedged upright, or you possibly can wrap a sequence with a light-weight load binder (a lever and cam machine used to tighten the chain) across the log and trestle. You can even improvise glorious bracing utilizing 1x1s lower to varied lengths and secured to the log and the trestles with field nails. With this technique it’s attainable to make any variety of light-weight staples in dimensions as wanted. They’re nearly free and have the benefit of being primarily wooden; there may be little probability of dulling an edge software. I typically start with two staples on both aspect of the far finish of the log, and one nailed on the alternative aspect from the place I start hewing. On an extended wobbly log I’ll set a fourth staple after I’ve hewn previous the primary trestle.

The hand grasps utilized in hewing are totally different from these used for chopping wooden. The most effective hewing grasp consists of holding one’s accustomed hand instantly behind the ax head (thumb prolonged ahead and fingers tucked near the deal with), with the unaccustomed hand someplace close to the deal with finish. Relatively than lean over the log, I want to bend each legs, holding my proper leg properly ahead (one thing like an advance place in fencing, however not as excessive). I like to face near the log, in order that my imaginative and prescient is straight forward alongside the hewing line. I take brief and deliberate strokes.

Rigorously hew down the right-hand vertical guideline on the log finish, with the size of the log in entrance of you. Begin with brief, cautious strokes. Maintain the ax barely askew (outward) so that you just chop a shallow bevel, attempting to separate the higher line, however cease after about 2-1/2 ft. Return and hew straight down, concentrating on the world between the log and the inside aspect of your ax blade.

I hew about half to 2 thirds by way of from the higher line, then transfer on. It’s simple in any other case to interrupt off wooden alongside the underside edge, or to go off plumb. One other benefit of not hewing straight by way of is that I’m frequently hewing into waste wooden, so the ax doesn’t fly free, throwing me off stability or out of rhythm.

Hewing is a ability that mixes muscular exertion with delicate accuracy. It’s essential to discover a regular rhythm. Hewing by way of knots takes further muscle; further scoring throughout and round them minimizes extreme tearing. Sliding your ahead hand towards the center of the ax deal with leads to extra energy. Attempt to take away skinny shavings.

After I get to the far trestle I take away the staple and renail it on the first trestle, if one isn’t already in place. I fastidiously hew down the vertical finish, stopping typically to look down the road. (It’s not seen from the hewing posture.)

In hewing two surfaces of the log, change staples and work down the opposite aspect. Flip the log over, restaple, and end hewing. For hewing a three- or four-sided beam, proceed the identical procedures. Chalk Strains for either side of the log could be taken from the unique horizontal pencil line made when the log was spherical. Scoring the third and fourth sides is awkward, as a result of it’s essential to see each hewn edges whereas sawing. If you happen to’re utilizing a chainsaw, I like to recommend stationing a pal on the alternative aspect who can sign simply because the cutters method the chalk line.

When you develop a really feel, it turns into attainable to hew pretty massive slabs and to maneuver alongside at a gradual tempo. In cool climate I hew one aspect of a 15-ft. log 15 in. in diameter in about half an hour. Seasoned consultants are significantly quicker. Nonetheless, the full time wanted to hew two sides of the identical log, from preliminary barking and structure to last hewing, provides as much as a number of hours. The job ought to be nearly excellent, requiring no touch-ups with an adze or slick.

Images: Tad Stamm

Carving a dough bowl

Log-Dwelling Woodworking

Cleaving Wooden

Join eletters right now and get the most recent strategies and how-to from Positive Woodworking, plus particular gives.