When contemplating veneer and its high quality, we often assume solely of traits reminiscent of species, thickness and determine, or defects reminiscent of knots, stain or pitch streaks. Past that, veneer is veneer. However of most severe concern must be knife checks. These are parallel-to-grain fracture planes produced within the veneer on the time of its manufacture and which can go unnoticed, solely to trigger agonizing issues later. As a result of they’re most likely the most typical reason for checks within the completed surfaces of veneered work, the woodworker ought to perceive what these knife checks are, how they’re fashioned, how one can detect them and the way to deal with them.

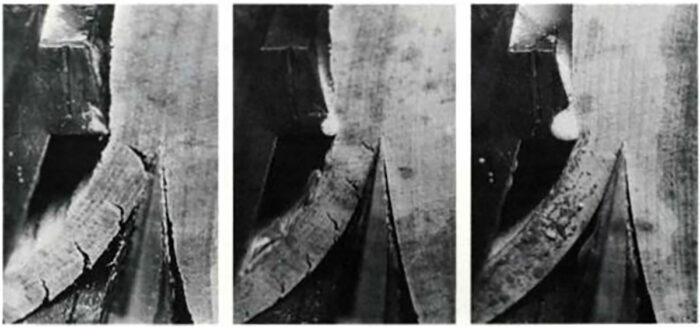

Sawn veneer doesn’t have these checks, however immediately most veneer is knife-cut by peeling (rotary slicing) or slicing. In both methodology, the essential slicing motion is analogous. A knife sharpened to an angle approaching 0º would distort the wooden construction the least, however would, after all, break too simply. Veneer-cutting knives are subsequently sharpened to an angle of about 21º—a compromise between a small angle that may decrease distortion of the wooden construction and a blunt angle that may decrease knife breakage. Because of this because the knife separates the veneer from the flitch, the separated layer of wooden is severely bent, and stresses construct up within the area close to the knife edge. When the energy of the wooden is exceeded, the stress is relieved by failure, and the aircraft of fai·lure thus fashioned known as a knife examine, or lathe examine. This bending and breaking cycle is repeated as slicing continues, so every layer of veneer has checks at pretty common intervals.

The facet of the veneer that was towards the knife and has knife checks penetrating into its floor known as the unfastened facet, or open face. The opposite facet known as the tight facet, or closed face.

To forestall knife checks, lathes and slicers are outfitted with a strain bar or nosebar, a stable bar or curler that bears towards the veneer as it’s being minimize. Its strain holds the cell construction collectively within the area the place checks often develop. An excessive amount of strain crushes the cell construction of the veneer, so there’s a theoretical optimum opening between the knife and the strain bar that produces the highest-quality veneer. Expertise has proven that checks may be minimized or eradicated when the gap between the strain bar and the knife is 80% to 90% of the thickness of the minimize.

The phrases tightness and looseness consult with the relative depth of knife checks. In producing veneer with out nosebar strain, tightness is improved by slicing lower-density species of wooden, by heating the wooden, and by skinny cuts.

Anatomical options of the species being minimize are additionally associated to checking. If structural planes of weakness-such as the big rays of oak or the earlywood layer in ring-porous hardwoods- coincide with the possible aircraft of examine formation, the checks shall be worse. Diffuse-porous hardwoods with fantastic, well-distributed rays usually tend to yield tight, uniform veneer.

The tightness of veneer may be assessed in quite a lot of methods. Floor roughness or corrugation (particularly of the unfastened facet) is usually related to checking. Veneer having any suggestion of a washboard floor might be loosely minimize.

Manually flexing the veneer will enable you to see the checks. As well as, the veneer will really feel stiffer when flexed to shut the checks, however will really feel extra limp when the checks are flexed open. Tightly minimize veneer will flex about as simply each methods, so if you happen to can’t inform, it’s most likely minimize effectively.

In some woodworking functions, it’s important to know the precise depth of the checks. This may be decided by staining with an alcohol or spirit resolution of dye reminiscent of machinists’ structure dye, then beveling the veneer. Minimize pattern strips of veneer from the ends of sheets and stain them liberally on either side, maintaining the stain away from finish grain. Enable to dry totally, then glue or cement the veneer onto blocks of scrap wooden. When the glue is ready, bevel the veneer with a fantastic sander disc, or with a pointy chisel or knife. The relative depth of the checks shall be obvious throughout the bevel .

The implications of knife checks must be fairly apparent. The commonest drawback is parallel-to-grain cracks within the end on veneered surfaces—practically at all times traceable to knife checks.

This drawback is particularly aggravating as a result of it’s often a delayed response, showing months or years after the piece is completed. A floor could also be flawless at completion, however the regular shrinking and swelling of the wooden in response to seasonal humidity fluctuation trigger hidden knife checks emigrate to the floor and thru the end itself. This drawback is second solely to delamination as a reason for the dangerous fame veneered merchandise have undeservedly acquired. One ceaselessly sees it when softwood structural plywood reminiscent of Douglas fir is used for completed or painted surfaces. Structural plywood is designed to hold stresses parallel to the grain course of its plies, and this functionality is little affected by knife checks. Apparently, little severe effort is made to manage tightness of veneer in manufacturing industrial softwood plywood. Plywood manufactured with surfaces of medium or high-density impregnated paper overlay (designated MDO and HDO ) is greatest the place clean painted surfaces are wanted. Giant lumber yards often inventory MDO plywood, which is routinely used for outside indicators and comparable merchandise.

Finish-grain plywood surfaces may additionally reveal end defects brought on by knife checks. That is particularly widespread when moisture loss ends in extreme shrinkage stress .

One other visible impact of knife checks is bleed-through of glue, which exhibits up as a sequence of evenly spaced traces on the veneered floor. That is particularly obvious in light-colored woods reminiscent of maple or birch sapwood.

In woodworking, veneer ought to routinely be inspected for tightness. Checks penetrating not more than 2 5 % of the thickness of the veneer may be tolerated beneath most circumstances. When laying up veneer, unfold the unfastened facet with glue. With luck, the glue will penetrate the checks and maybe glue them closed. It might assist to put the veneer over a barely convex floor so the checks shall be open to the glue. (This may also be sure that the tight facet is the uncovered face on floor plies. ) Care should then be taken to not sand by means of the tight facet of the veneer. I’ve seen numerous conditions the place veneer surfaces have been sanded proper down to show the knife checks and the glue in them.

Bookmatched surfaces are a predicament, as a result of the veneers should be positioned with alternate open and closed faces up. In such circumstances, you will need to have comparatively tight veneer to make sure uniformity. You could have seen bookmatched patterns by which the end high quality alternated with each bit of veneer, a consequence of knife checks.

Lathe-check troubles will not be restricted to visible floor results. Vital mechanical issues may additionally consequence. Most common is a few type of rolling shear developed when plywood is harassed within the type of a beam over a brief span, so that prime ranges of horizontal shear are developed. If the shear coincides with the course of stress that opens the checks, rolling shear failure might consequence. The sides of plywood panels ” broomed” over on this method are sometimes misinterpreted as “delamination, ” which erroneously implies glue failure.

I don’t have any particular suggestions for ending veneer that has knife checks. I feel a end that would supply the most effective moisture barrier and thus scale back dimensional variation could be greatest. Additionally, if the checks had been on the floor, any end that may seal them shut would assist. A end like linseed oil would have little to supply. A low-viscosity lacquer or varnish in a number of coats may work greatest.

On the entire, most hardwood cupboard veneer produced by respected mills is minimize with enough manufacturing high quality management to make sure cheap tightness. However watch out for ” clearance” gross sales or “closeouts, ” as a result of unfastened veneer is hardly a discount at any value. The very best guideline is to purchase veneer from respected sellers and know how one can detect, and deal with, the occasional unfastened veneer.

To view your entire article, please click on the View PDF button beneath.

Nice Woodworking Advisable Merchandise

Bahco 6-Inch Card Scraper

The scale and thickness are what matter right here. A constant performer, this Bahco scraper is discovered in lots of retailers we go to.

Whiteside 9500 Stable Brass Router Inlay Router Bit Set

Set contains stable carbide down-cut spiral bit (for chip-free slicing), quick-change bushing, template information and full directions. Matches Porter-Cable, Black & Decker and any router with a Porter-Cable bushing adapter.

Join eletters immediately and get the newest methods and how-to from Nice Woodworking, plus particular provides.

Obtain FREE PDF

whenever you enter your e-mail handle beneath.

View PDF