There are occasions in woodturning when the necessity arises for “inventive” or customizable work holding on the lathe. There are commercially obtainable options resembling flat jaws, comfortable jaws, vacuum chucks, and so forth., however these instruments have limitations. Value will be one such limitation; it might be troublesome to justify the associated fee for a possible single-use answer. A jam chuck is a superb possibility, as a result of it’s infinitely customizable and constructed of scrap materials you already personal. A jam chuck holds objects on the lathe using a wood-on-wood friction joint. This wood-on-wood joint won’t mar a completed piece so it may also be used on tasks that want touching up.

I used to be not too long ago commissioned to make a classroom set of spinning tops for my spouse’s co-worker. Whereas making these tops, I used to be ready to make use of jam chucking to make extra environment friendly use of supplies. I began with a 1-1/2 in. sq. by 6-in.-long clean, which allowed me to make three tops from every part, leaving a scrap simply large enough for an additional prime. That final piece normally presents a problem as it could necessitate working too near the chuck jaws. I used to be ready to make use of a jam chuck to reverse-mount the spinning prime and end the underside. Jam chucking is usually a very correct means of remounting workpieces.

A spinning prime should be precisely circled a single middle level to work nicely. I began by shaping and texturing the highest aspect of the highest.

There may be not sufficient room between the spinning prime and the chuck jaws for shaping, texturing, and parting.

Jam chuck to the rescue!

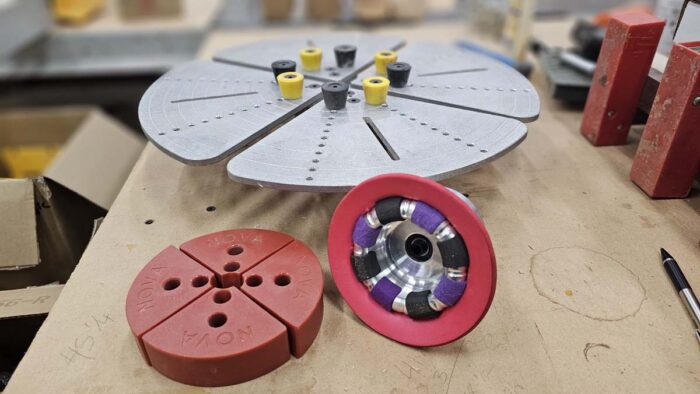

To make use of a jam chuck, mount a block of scrap within the chuck and bore a gap via the middle with a spindle gouge (a drill bit might be used additionally) to make room for the deal with of the highest. Lower a recess with a parting instrument that may simply match the diameter of the outer fringe of the highest. The recess may also present good registration because it holds the spinning prime across the prime nook, gripping the sting and referencing the face. This match must be very tight and will take a couple of tries to get it excellent, however it’s value it.

Insert the spinning prime deal with finish first and faucet it in with the butt finish of your chisel. At this level, the spinning prime will be formed and embellished.

|

|

After eradicating the jam chuck with the spinning prime hooked up, a dowel or compressed air can be utilized to push the spinning prime out of the tight-fitting jam chuck.

Or, reusable comfortable jaws is perhaps higher

As a bonus, an adjustable jam chuck might be made by creating DIY comfortable jaws on your chuck.

|

|

The instance described right here is just one of many many makes use of for a jam chuck. Jam chucks can be utilized for giant and small tasks, every part from jewellery pendants to bowls. The subsequent time you’re offered with a troublesome holding state of affairs, get inventive and use a jam chuck.

-Darryl Jones is a Effective Woodworking Ambassador. He enjoys empowering others via educating and sharing data and strategies. His social media deal with is Dread Knot Woodshop (YouTube, Instagram) as a result of he believes that we’re all able to greater than we understand. Therefore the tagline “Dread Knot and Make One thing.”

A Woodturner’s Information to Chucks and Jaws

The right way to get a glass-smooth floor on turnings

Compression Chuck for a Lathe

Join eletters at this time and get the newest strategies and how-to from Effective Woodworking, plus particular presents.