When my spouse, Rachel, stated she wanted a small basket to carry mending provides, I made a decision that the standard instrument tote was the proper inspiration for the challenge. The shape has been round for lots of of years and is available in many sizes and variations. It’s a flexible design that may be expanded to suit any want and use you will have.

For this tote, I made a decision on dovetails to hitch the ends to the underside, and through-tenons to safe the deal with. The stub tenons on the angled sides match into grooves within the ends. The result’s a sturdy tote that provides some enjoyable constructing challenges however gained’t tie up your store for too lengthy.

Design is a vital a part of the constructing course of even on easy initiatives. Whereas I had an thought of how I wished the tote to look, getting the general dimension proper was important to its performance sooner or later. One thing too massive and clunky, or too small to be helpful, would discover itself tucked away in a nook someplace. So Rachel and I took a minute to stroll by means of the home and have a look at containers and bins to assist decide dimension. I discover an exercise like this to be far more practical than asking for dimensions from a consumer. I then made a fast mock-up out of MDF and introduced it into the home for a take a look at drive. As soon as we had decided the ultimate dimension, I used to be able to mill up some lumber.

Dovetails and through-mortises earlier than shaping

|

|

The ends are joined to the underside with easy through-dovetails. To make the method simpler, lower and match the dovetails earlier than the ends are sawn to form. However think about the ultimate form of the ends when laying out the tails. A great way to do that is to attract the form on one of many ends after which lay out the tails in order that they’re centered on the profile. It is going to look a bit unusual till you narrow the ultimate form. The dovetail pins and tails are happy with the floor. To perform this, set a marking gauge to roughly 1/16 in. over the thickness of the inventory when scribing the bottom traces.

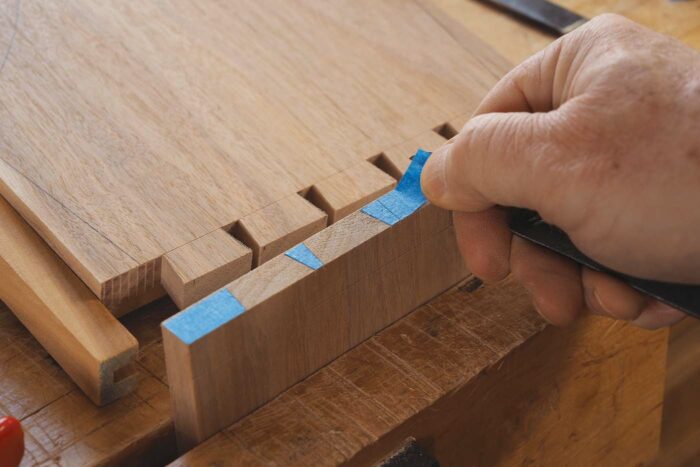

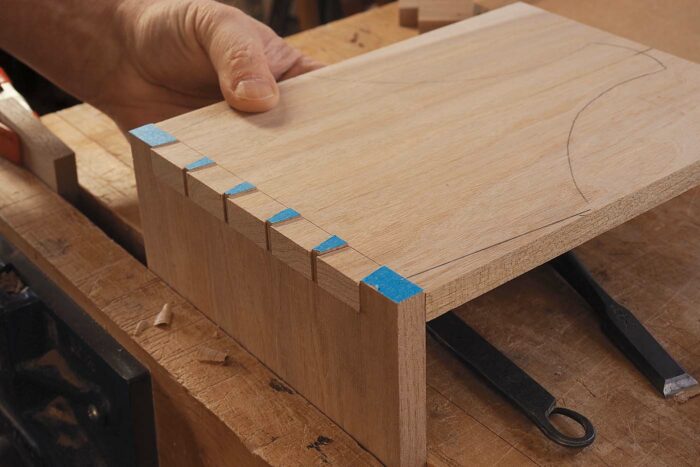

After chopping the tails, switch the tail areas to the pin board. Correct format is important right here. Making use of tape to the top grain will get you off to begin. By scribing by means of the tape and peeling it away from the waste areas, you’re left with a transparent roadmap for chopping. As well as, should you stray out of your traces with the noticed, the tape will function a information for paring. The following problem is to place the tail board precisely when scribing. A bit of 1/4-in. MDF clamped alongside the baseline of the tail board acts as an efficient information when positioning it on the top of the pin board.

Lastly, strike a pencil line down the face of the pin board at every pin location. This offers a visible information when sawing and can supply clues when paring the partitions vertically throughout becoming. If it’s been some time because you picked up your dovetail noticed, clamp an offcut into your vise, scribe some vertical traces down the face, and take some warm-up cuts; as soon as you end up hitting your line as a rule, you’re prepared to chop some dovetails. After sawing the pins, take away many of the waste between them with a coping noticed or fretsaw. Then chisel or rout to the baseline, and pare the pin partitions.

The primary process when becoming the joint is to guarantee that the partitions of the pins are vertical. Out-of-square partitions could cause the boards to separate once you’re driving the joint house. If that the partitions are vertical, you generally is a bit extra forceful when seating a joint.

With the dovetails full, lower the mortises for the deal with. To put them out, first apply tape to each faces of every finish. Then use a marking gauge registering off the edges of the board to scribe the mortise partitions. You’ll use a 3/8-in. bit to drill out the waste earlier than chopping, so lay out the mortises barely wider than the bit to make it simpler to keep away from drilling outdoors the scribe traces. As soon as the waste has been drilled out, chopping goes rapidly. Work midway in from every face to make sure clear surfaces.

As soon as the ends are mortised for the deal with, it’s time to noticed them to form. The tote sides might be tenoned into grooves that run parallel to the top boards’ angled edges. To simplify grooving, it’s best to chop the angles first after which use them as a information when routing. The precise angle isn’t necessary; nevertheless, it’s important that the angles on each ends match one another. A easy strategy is to tape each ends collectively when chopping them out. After bandsawing to the format traces, use a hand airplane to true the angled sides. Smoothing the curves could be tackled with a file, a spokeshave, sandpaper, or a mix of all the above.

I don’t have a fence for my small plunge router, so I hooked up a information block to the bottom. Make a full-depth plunge at every finish of the groove, after which rout the groove with a number of shallow passes.

To trim the underside to remaining width, dry-fit one finish to the underside. Place a 1/16-in. shim in opposition to the sting of the top and pencil the ultimate profile on the underside. Tilt the desk noticed’s blade to the identical angle as the edges to tear the underside to remaining width.

Lower the stub tenons on the ends of the edges on the desk noticed. Dry-fit the tote backside and ends to measure the shoulder-to-shoulder size of the edges. Use a dado blade set wider than the specified tenon, and overlap a portion of it with an L-fence clamped to your rip fence. Utilizing the miter gauge, begin a bit too lengthy, and sneak up on the ultimate size by adjusting the rip fence. To chop the angled edge alongside the underside of the edges, tilt the blade to match the angle of the ends. The highest edge is left sq. and rounded with a block airplane.

The deal with completes the tote

Whereas the opposite elements of the tote are made out of butternut, I used ash for the deal with. The colour distinction is sweet, and ash is a harder wooden, permitting me to present it a thinner profile whereas sustaining power.

|

|

Lower the tenons and the recess for the twine wrap earlier than chopping the curves. As soon as once more, you’ll have to sneak up on a remaining size. I like to finish up with a tenon that extends farther from the face than the dovetails do, roughly 1/8 in. This permits me to angle the top to match the radius of the deal with’s curve. It’s a small element, however a pleasant one. As soon as the tenons are full, use a dovetail noticed to kerf them for wedges.

The highest and backside curves of the deal with have completely different radii. Utilizing a curve with a smaller radius for the underside edge leads to a deal with that’s narrower on the middle than the ends, giving it a lighter, much less clunky look. It’s a way that I exploit typically in my work. After bandsawing, clear up the curves with a block airplane, leaving heavier sides that can add a tactile high quality when somebody lifts the tote.

As soon as the curves are full, lower shallow twine recesses alongside the highest and backside edges to match these on the faces. The 1/16-in. recess offers a pleasant seat for the twine, which I add after making use of a coat of shellac to the deal with. Utilizing 4mm hemp twine, start the wrap by trapping the top underneath the primary 5 – 6 wraps alongside the underside of the deal with, after which trim it with a knife. Proceed wrapping the deal with, stopping 4 or 5 wraps in need of the far finish. Bend a brief size of baling wire right into a U. Maintain it in place alongside the underside of the deal with and proceed wrapping over it. When you attain the top of the recess, thread the top of the twine by means of the U within the wire and use a pair of pliers to tug the wire underneath the wrap, pulling the twine finish with it. Slip a knife between the wraps the place the twine finish exits to trim the top of the twine. Watch out to not nick the wraps.

End first, then glue

On a small challenge like this, you possibly can normally get by with making use of two coats of thinned blond shellac. For those who’re working from a can, skinny the shellac 1:1 with denatured alcohol. Aircraft or sand the elements to not less than 400 grit, and wipe on a coat of shellac, steering away from glue surfaces. As soon as the shellac is dry, which gained’t take lengthy, give the elements a fast sanding with tremendous sandpaper to knock down any raised grain. Then apply a second coat of shellac. I normally cease right here on a challenge like this. Be at liberty so as to add one other coat, however watch out to keep away from constructing a floor that’s too shiny. To my eye, it doesn’t match the look of a utilitarian piece like this. If the floor does get a little bit shiny, wait till the tote is assembled after which add a coat of paste wax utilizing 0000 metal wool to tone down the gloss and create a satin sheen.

Glue-up is a little bit difficult as a result of all the pieces should come collectively without delay. I don’t flush the joinery after gluing, so I attempt to reduce squeeze-out. On the dovetails, apply glue solely to the aspect partitions of the pins. Add a dab of glue to the grooves within the ends, however not the aspect tenons themselves. The tenon on the deal with is a through-tenon, so apply glue solely to the tenon and never the mortise. While you’re making use of glue to the tenon cheeks, attempt to work a little bit into the wedge kerf when you’re at it.

|

|

For glue-up, lay one finish flat on the bench and insert the underside, deal with, and each side. Then add the second finish. Ensure that the aspect tenons are aligned with the grooves earlier than making an attempt to seat the ends totally. When clamping, be certain that the edges sit flush to the underside. Wedging the deal with gained’t pull the joint tighter, so be certain that the edges are clamped flush to the deal with’s tenon shoulders earlier than driving within the wedges. After the glue dries, trim the wedges and sand them flush. Any areas of squeeze-out ought to pop off simply from the completed surfaces with a chisel. Add a lightweight spot coat of shellac the place wanted.

Michael Pekovich, Superb Woodworking’s editor and artistic director, teaches woodworking across the nation.

Superb Woodworking Beneficial Merchandise

Suizan Japanese Pull Noticed

A flexible noticed that can be utilized for something from kumiko to dovetails. Mike Pekovich recommends them as a woodworker’s first handsaw.

Join eletters in the present day and get the newest methods and how-to from Superb Woodworking, plus particular provides.