The stable wooden tiles on my chairs are strung on high-grade polyester rope pulled taut between the perimeters of the chair. I prepare the tiles in a running-bond sample (borrowed from brickwork), which is visually engaging but additionally hyperlinks the tiles collectively in an interlocking net.

Tilemaker

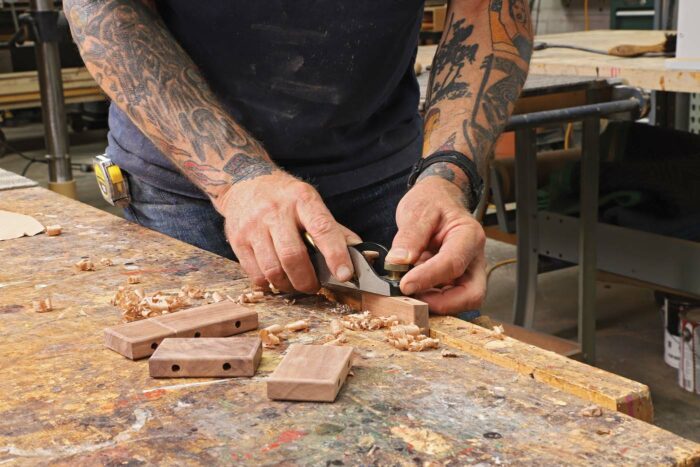

The wooden I exploit for the tiles is predominantly cutoffs, so the method of tilemaking begins on the bandsaw, the place I reduce scraps to tough width earlier than milling them to thickness. Then it’s on to the desk noticed, the place I rip and crosscut the tiles to remaining dimension. Afterward, I rout all the sides with a 1/8-in.-dia. roundover bit.

|

|

|

To supply a running-bond sample, that you must begin each different lengthwise row of tiles with a half tile. To make this work, I produce a batch of one-and-a-half-length tiles, becoming a member of two full tiles finish to finish with Domino tenons after which reducing them to size.

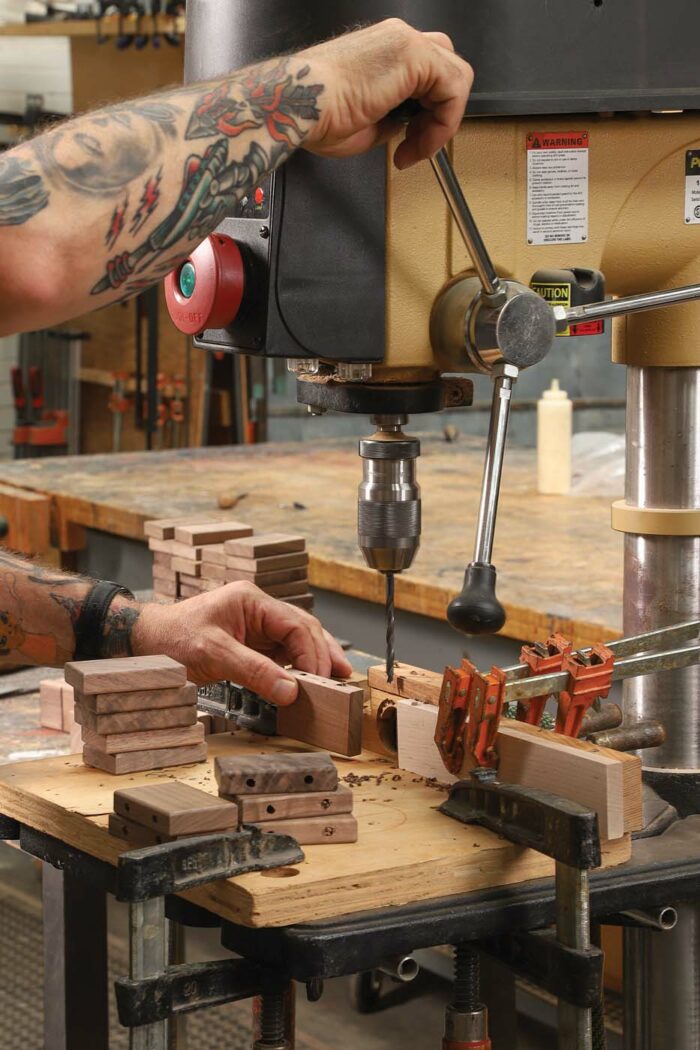

Subsequent, I drill rope holes via the tiles. Gap patterns are intuitive for working bond: two holes in every common tile, drilled 1 / 4 of the tile’s size from every finish. (For instance, a 4-in.-long tile would have its holes 1 in. from every finish.) I middle the holes within the tile’s 5/8-in. thickness, so I don’t have to fret about which face of a tile is up once I’m stringing them.

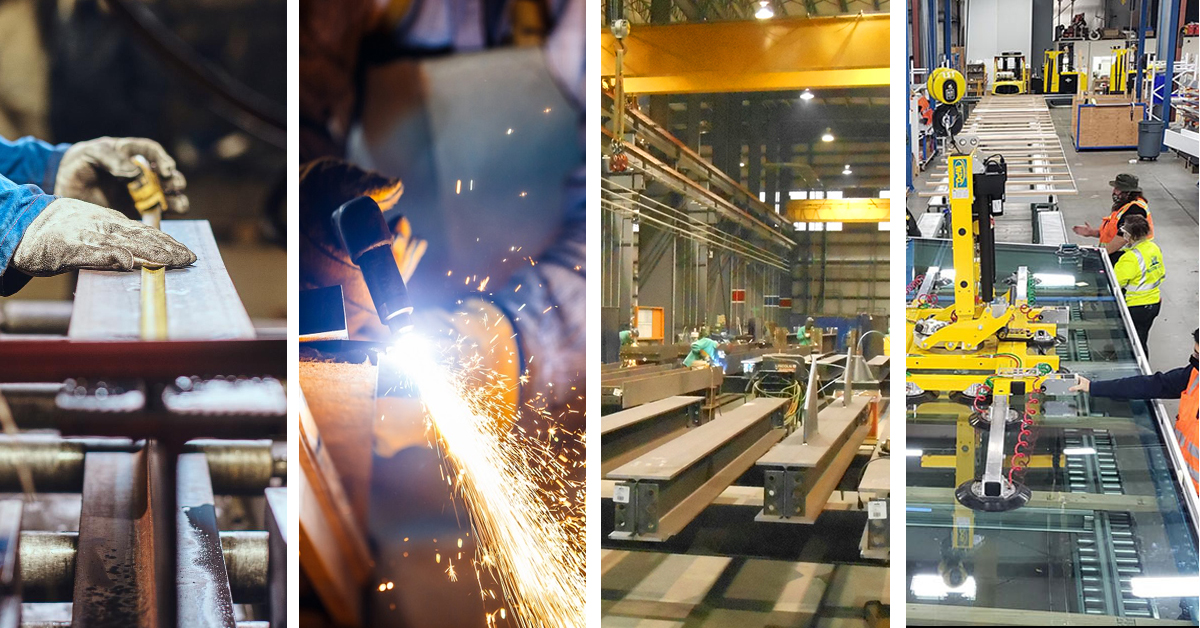

There’s plenty of drilling concerned in one among these chairs! I made a fence for my drill press with a vacuum port positioned so it holds the tile tight to the fence throughout drilling, then sucks up chips afterward. I exploit a 1/4-in.-dia. bit and drill midway via from one edge, then end the outlet from the opposite edge. Clear holes are crucial, however with my system it’s fairly straightforward.

|

|

| The working bond begins. After tying a sq. knot at one finish and passing the rope via the primary gap on the entrance of the seat, thread on 9 tiles to make the primary row, alternating full-length and one-and-a-half-length tiles. | |

I run the grain of the tiles parallel to the perimeters of the chair, so there’s some tightening and loosening throughout the width of the tile fields in keeping with the seasons. I make the seats 18 in. broad—9 rows of 2-in.-wide tiles—which makes for a great, snug seat whereas retaining the full seasonal wooden motion average. After I construct a chair in the summertime, I be certain that the tiles are tight aspect to aspect; within the winter I just like the tiles to be free and wiggly when they’re strung collectively. To regulate the match, I alter the size of the struts and again rails by as much as 1/8 in. if want be.

Getting ready to weave

I all the time lay out the total tile fields on the worktable subsequent to the chair body I’ll be weaving. As a result of they’re produced from scrap, the tiles sometimes have a great quantity of distinction in colour and determine, and I attempt to prepare them in a delightful, random composition. As soon as I do know which tiles can be the place, I reduce a 5° bevel on the skin edge of every tile that can be adjoining to a chair aspect. The bevel permits the seat’s tile subject to flex downward and the again’s subject to flex again. The uncovered finish grain of the top tiles additionally will get finely sanded at this level. Subsequent, I oil all of the tiles one after the other, selecting them up and changing them within the composition.

Weaving wooden

Polyester rope is available in varied colours, however I exploit black. The usual 1/4-in.-dia. rope I exploit (which I order in 500-ft. rolls) is one of the best that I’ve discovered—robust and no stretch. I’ve tried high-tech crusing rope, comparable to Dyneema, however the poly beats it for chairs.

After figuring out the lengths of rope wanted, I reduce items for the seat and again. I rigorously soften a pair inches on the main finish of the rope with a propane torch, pulling and stretching as I apply the warmth. This stiffens and thins the rope, making it simpler to string via the tiles and the body. I’m cautious to not soften it solely or set it on fireplace. On the trailing finish of the rope I tie a sq. knot, which is able to cease the rope from pulling right through the body.

After threading the ready finish via the chair aspect, I begin including tiles, selecting them up within the order that they’re laid out. I sometimes begin on the entrance of the chair seat and work my method to the center, often pulling the whole lot taut. As soon as I get half the tiles laced, I thread the rope via the additional gap on the center of the chair aspect and safe it to the cleat connected inside.

|

|

|

Then I begin weaving from the again of the seat, working my method to the center. As soon as all of the seat tiles are strung, I tighten the rope, rigorously however forcefully pulling it taut with needle-nose pliers at every gap within the chair aspect—assume lacing an ice skate. I end by pulling the slack via the cleat and cinching it tight. After trimming the surplus, I soften the top so it received’t fray.

|

|

|

|

|

The again is woven in a lot the identical method because the seat, however with a single size of rope threaded via the entire subject. As soon as all of the again tiles are strung, I exploit the needle-nose pliers once more to take away the slack after which tie off the rope with a sq. knot, pulling it as tight as I can since there isn’t the advantage of a cleat on the chair again. I go away about 4 in. of rope dangling from the highest knot and slide on three or 4 turned beads as an ornamental ingredient; then I tie one other sq. knot to carry the beads. To finish the chair, I trim and torch the rope ends.

-Scott McGlasson is an expert furnishings maker in Minnesota.

To view the complete article, please click on the View PDF button beneath.

Protected method to rip unwieldy workpieces

Weaving Shaker Tape Seats

Methods to weave a rush seat

Join eletters right this moment and get the most recent strategies and how-to from Nice Woodworking, plus particular affords.

Obtain FREE PDF

once you enter your e-mail handle beneath.

View PDF